By Mike Switzer, Product Line Manager - Motors

Vibration analysis is an essential maintenance process for electric motors today. This article breaks down everything you need to know about vibration analysis to ensure your facility’s motors are running at peak efficiency.

What is Vibration?

In a dictionary, you might see vibration defined as “to swing back and forth; to oscillate.” In the electric motor industry, vibration is known as the pulsating motion of a motor or part of a motor from its original place of rest. Vibration is a response to an internal or external force applied to the system.

How is Vibration Analyzed?

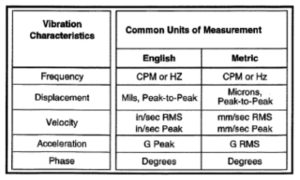

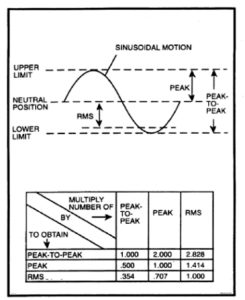

Three main vibrational parameters can be measured: amplitude (how much), frequency (how many times per minute/second), and phase angle (describes how it is vibrating). Each measurement is important to define how and why a machine is vibrating. Vibration analyzers measure vibration using a capable device that records vibrations across a wide range of amplitudes and frequencies.

Four descriptive characteristics we use to understand and assess the behavior of vibrating systems.

Displacement – typically uses mils (thousandths of an inch) to quantify the total overall movement of the mass when it vibrates.

Velocity – Velocity vibration is the speed at which the mass is moving or vibrating during its oscillations. It will be expressed in units of inches per second or millimeters per second (in/sec or mm/sec).

Frequency – Frequency is the measurement in a period of time (T) of one cycle and inverting to determine the frequency. Frequency is expressed in units of either cycles per minute (CPM) or in cycles per second (CPS), which is also referred to as Hertz (Hz).

Phase – Vibration phase is the final descriptive characteristic of vibration. Phase is the relative shift of a vibration part to a fixed reference point on another vibration part. Meaning, phase is a measure of the vibration motion at one location relative to the vibration motion at another location. We also call this the “timing” of vibration in relation to a stationary or moving part on the motor or machine.

Today’s vibration analyzers are extremely accurate for determining a vibration fault. The analyzer will be able to plot the necessary vibration you are measuring . Displaying this information requires a very precise method. To simplify the process, vibration analyzers create what we know as a Fast Fourier Transform (FFT). An FFT is the microprocessor transformation from time-domain data (amplitude vs time) into frequency-domain data (amplitude vs frequency). Baron Jean Baptiste Fourier developed this technique over 100 years ago. Fourier stated that any real-world sine waveform can combine to make another more complicated waveform.

Why is Vibration Analysis Important?

Periodic vibration analysis can determine what mechanical condition an electric motor is in. Keeping an eye on unwanted vibration frequencies in the bearings is a must-do process. Vibration analysis is also important for inspecting the condition of ball and sleeve bearing units. This doesn’t’ just apply to mechanical portions of an electric motor — it can also apply to frequencies generated from the electrical currents in the windings to the rotor. Other issues may arise during analysis that show internal electrical issues that need attention.

To prevent production losses, you need to ensure motor reliability and longevity. Periodic vibration inspections are essential to this!

Vibration Analysis at Southwest Electric Co.

At Southwest Electric Co, our experienced experts specialize in vibration analysis for electric motors. We can help you problem solve quickly to get a poorly performing motor back at peak performance, plus we can put a plan in place to prevent future efficiency issues.

Give us a call, email, or request a quote using the button below to get in touch with us today.