By Mike Switzer, Product Line Manager - Motors

During the life span of every 3 phase electric AC motor, the stator windings will need to be rewound. The timing of a needed motor rewinding will vary according to the application and environment. Mechanical failures could also cause the rotor to fail unexpectedly, calling for a rewind. When stator windings do fail, there are many items to address to get the stator back to its original manufactured state or better. The manufacturer may design the horsepower, torque, and KVA code to its limits when designing how much ground wall protection the coils can absorb with a limited amount of slot width. Other manufacturers will place enough ground wall insulation to cover the temperature range the motor was designed for and have ample amount of slot width to do so.

1 – Determine the Winding Data

Before motor rewinding can begin, we must determine the winding data. To do this, all AC motor VPI stator windings will need to go through a process where the unit is placed in a high-temperature burn-out oven. These ovens are designed to burn the existing varnish out of the coils in order to soften them up for extracting. The typical temperature for this process is 650°F. Varnish flare-ups have the potential to damage the iron core, so it is important that the oven is equipped with water sprayers to alleviate any excess fire that may occur during the process. After the burnout process is completed, supplemental data can be determined. The type of connection, groups, wire size & turns per coil are especially important.

Pre & Post Burn Core Tests

Additionally, data must be taken for the iron core slots. A pre-core test before a burn cycle is a must. This will determine if the iron core was able to succumb to the high-temperature burn. After the burned coils are stripped from the iron core, the core is washed clean of any debris and put through a bake cycle between 250°-285°F for several hours to remove any residual water and prevent any further flash rust. The iron core will have another core test performed, post-burn. This will confirm that the iron core is still usable and was not damaged during the burn cycle.

Manufacturing & Further Prep

Once the coil data has been verified by engineering, a full set of coils will be manufactured. The coils will have insulation that is not impregnated with varnish. During this time, the stator will be blasted in preparation for the winding process. Instead of using abrasive media like silica sand (which creates a high friction temperature that could cause damage to the iron), it is optimal to use walnut shell media to sandblast the stator. This will alleviate any damage to the end of the slots. Specifically, where the finger plates are pressed against the end of the iron core.

2 – Prep the Stator for New Coil Insertion

The stator slots will be investigated for any sharp edges and filed when necessary prior to coil insertion. Then, the bottom of the slots will be filled with a glastic filler for insulation to ground the bottom side of the coils. Once the coils reach the span between the top and bottom side of the coils, another filler of glastic will separate the top and bottom in the same slot.

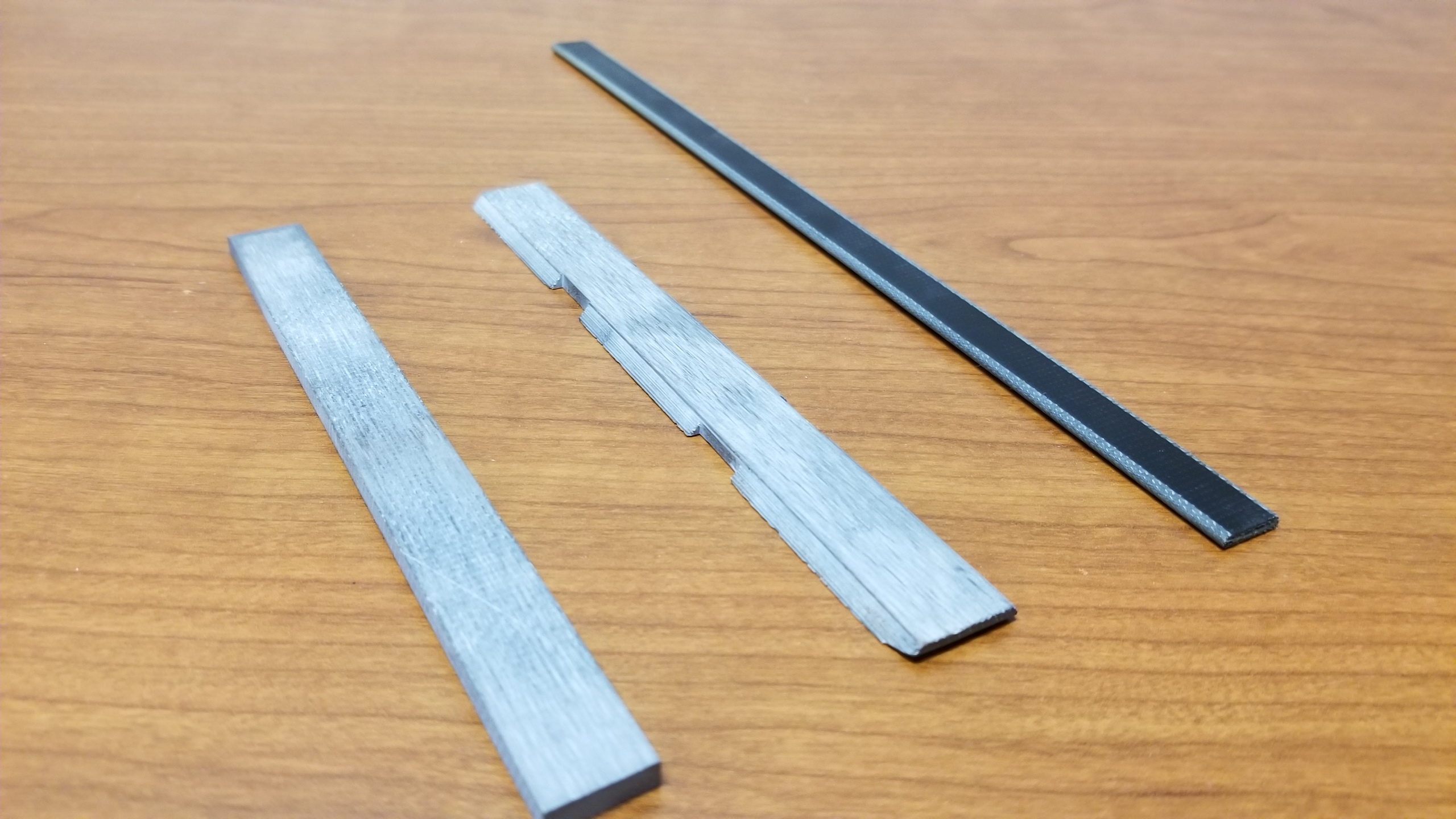

Some motors require magnetic wedges, while some do not. Motor manufacturers place magnetic wedges within the design to seal the open-slot design for form-wound induction stators and reduce the air-gap flux distortion, magnetizing current, starting (in-rush) current and temperature rise. Benefits of magnetic wedges include an increase of motor efficiency and improvement of power factor.

There can also be cost savings from a reduction in active material or frame size. End users can make better purchasing decisions with an understanding of the cost impact of magnetic wedges. Magnetic wedges have been known to work their way loose out of the wedge groove causing issues, such as the coil vibrating and creating a ground wall short circuit from the movement of the coil. Or, if one or more wedges get trapped between the rotor and stator iron, the wedges could become loose from the wedge slot. At that time, the wedge(s) can impinge a coil and damage the insulation causing a path to ground. Another potential problem could occur if the coil in the slot vibrates, causing the insulation to become compromised.

So, it is not always a good idea to place magnetic wedges in place of a standard glastic type wedge. Different styles of magnetic wedges are shown below. This can cause efficiency errors with the magnetics being produced by the iron core.

3 – Insert Coils

Taking care of the non-varnished coils during insertion is pivotal to prevent any nicks or cuts on the coil insulation. Thus, the prepping of the stator slot is important. Once the coils are inserted, the defined connection for the groups will be the next process. Placing the proper amount of mica/glass insulation over the silver soldered connections is also critical. All connections are tied down with a resin-rich fiberglass tape that will harden during the curing process. External leads are now added to the winding, and the unit is ready for the VPI (Vacuum Pressure Impregnation) process.

The VPI Process:

The stator is placed in a bake oven at or about 275°F and warmed up completely. The stator is then placed in a VPI vessel. A vacuum pressure cycle is performed prior to the varnish filling the VPI vessel. After the vacuum pressure cycle is completed, the varnish is moved from the holding tank and the dipping vessel is filled to the proper level in order to cover the entire non-varnished coil windings.

This process takes up to 10-14 hours. After the VPI cycle, the unit is placed back into the bake oven for curing. Curing can take up to 15 hours, depending on the coil size and amount of insulation used during coil manufacturing. After curing, the stator is cooled off and all excess cured varnish is removed. At last, the newly rewound stator is ready for assembly. SWE offers a 3-year limited warranty on all VPI style motor rewindings. A VPI winding can last 10-20 years if the motor application is not detrimental to the overall conditions of the motor.

At SWE, we take pride in producing data-driven, high-quality, and efficient motor rewinding intended to significantly extend the life of any motor. It is our pleasure to share our expertise and craftsmanship with our customers to keep their production up and running.

Visit our Industrial Motors page to learn more, or call or email us now!

If you also have questions about DC motors, check out our blog “6 Common DC Motor Issues.”

Stay connected.

Follow Southwest Electric on LinkedIn and Facebook

to see regular posts about our current projects.