By Kevin Bachhofer, Operations Manager - Motor & Field Service

At Southwest Electric Co, we know how important electric motor preventative maintenance is when it comes to increasing the life span and overall functionality of the motor. When creating a maintenance routine, a multitude of factors come into play such as ambient operating temperatures, run times, loading, types of driven equipment, and special environmental conditions. One plan certainly doesn’t fit all, but there are several common procedures that are standard to most maintenance programs.

Bearings must be lubricated to prevent premature failure due to overheating caused by friction and contamination. Motors equipped with filters must be cleaned to allow proper cooling air to enter the motor without introducing dust and other contaminants that clog stator vent holes. Alignments should be checked to prevent shaft and bearing stress. Electrical testing should be performed to help prevent possible motor failure. Vibrational analysis of the equipment can also be used to serve as a baseline during future checks that can catch smaller issues before they become serious failures. Lastly, a simple visual inspection can help identify present and future problems. Below, we dive a little deeper in explaining these six maintenance procedures.

1- Bearing Lubrication

Bearings come in many types and sizes, but they all require regular lubrication, which commonly comes in the form of grease or oil. Greased bearings can be serviced manually or with programmable auto-lubers to supply the recommended amount of grease to the bearing over a calculated period of time. Both methods have their advantages and disadvantages, but supplying fresh grease to the bearings is key. Oil bearings, whether sleeve or ball, require oil changes to maintain the proper viscosity of oil to keep the bearings cool and lubricated. These oil changes also serve as a health check to see if contaminants are entering the bearing chamber or metal particulates are present indicating possible excessive wear.

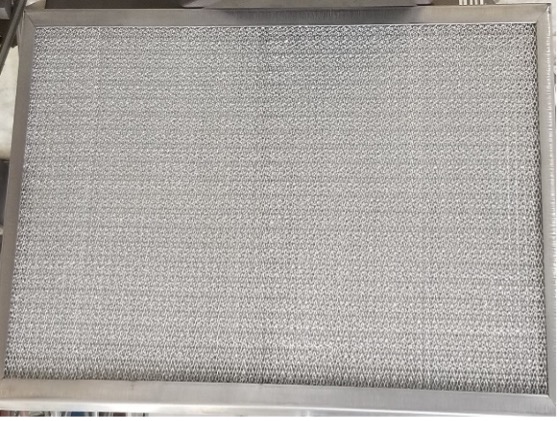

2- Cleaning the Filter

Filters are critical to keeping you motors cool and blocking out dirt and debris. Dirt and debris can settle in the motor and seriously impacting the motor’s life span. Sand and other abrasives that enter the rotor and stator area at high velocity can act as a sand blaster, eating away at the stator and rotor. Main filters and pre filters are designed to capture these contaminants and block them from entering the motor. However, these filters are only as good as what they are designed for and should be cleaned on a regular basis depending on the levels of airborne contaminants at your location. Clogged filters starve the motor of cooling air and can overheat the motor causing shutdowns and possible damage.

3 – Aligning the Motor

Motor alignments reduce the stress on the motor and driven equipment. Annual laser or dial indicator alignments can catch misalignments resulting in bearing failure, seal wear, overheating issues, damaged or worn couplings, and possible broken shafts. Both types of alignment devices are effective and have their advantages over the other. Laser alignments take much of the guesswork out of the addition and removal of shims, but can sometimes be difficult in certain lighting or tight spaces. Dial indicators are great in tight spaces and all lighting conditions but require more calculation and attention to perform the alignment. It is important to choose the right kind of alignment for your motor to make sure the alignment is maintained with preventative maintenance.

4 – Electrical Testing

Annual electrical testing and inspection can be integral in catching early issues with failing winding insulation, loose terminations, and preventing further deterioration. Electrical testing can detect moisture in the windings, as well as preventing a possible failure during start. Testing of RTDs for the stator and bearings can eliminate false temperature readings through monitoring equipment and prevent nuisance shutdowns. Electrical testing is also used to confirm functionality of space heaters to keep moisture out of motors while idle. From these inspections, visible wear, rubbing, loose terminations, and failing taped connections can all be addressed before they result in a motor failure.

5 – Vibration Analysis

Vibrational analysis of equipment could be the sole topic of a great many preventative maintenance discussions. Base readings collected can show deterioration, wear, electrical issues, loose and misaligned equipment, and determine which issue is affecting your motor. This becomes an invaluable troubleshooting tool once an issue has been identified.

6 – Visual Inspection

Finally, one of the most important parts of any maintenance program could be the visual inspection. Looking for leaks, missing covers, scorched paint, rusting, and signs of damage can be instrumental in keeping motors running for longer intervals. With the increasing costs of shop repairs, the value of a quick visual inspection can’t be overstated.

These items represent some of the more basic things to think about when establishing a preventative maintenance plan. If taken into consideration, along with the conditions the motor will be operated in, a plan can be tailored specifically to keep your AC or DC motors running better, longer, and be more cost-effective.

Southwest Electric Co. is here to help with all of your motor preventative maintenance needs. Give us a call, email, or request a quote using the button below to get in touch with us today.