By Ray Urbanic, P.E., VP of Engineering

Perhaps your assignment is to make sure your facility is meeting NFPA 70E compliance or someone hands you arc flash assessment results and asks to provide your manager a “quick summary” or you’re just curious of the arc flash risk in your facility and want to understand it better. In any case, they hand you either a large binder or several PDF files of 150+ pages of text, charts, and various lists of data that would take days to plow through. There is a wealth of information included in a properly-prepared arc flash assessment, when there’s time to mine it. But if you’re in a hurry, there’s a much faster way to get to the heart of the assessment, if you know what to look for.

First, most assessments will include an Executive Summary, which is you can find toward the beginning of the assessment and should provide a concise summary of the most interesting findings as well as identify the greatest risks. This will give you a good idea of what to look for in the Arc flash Results tables.

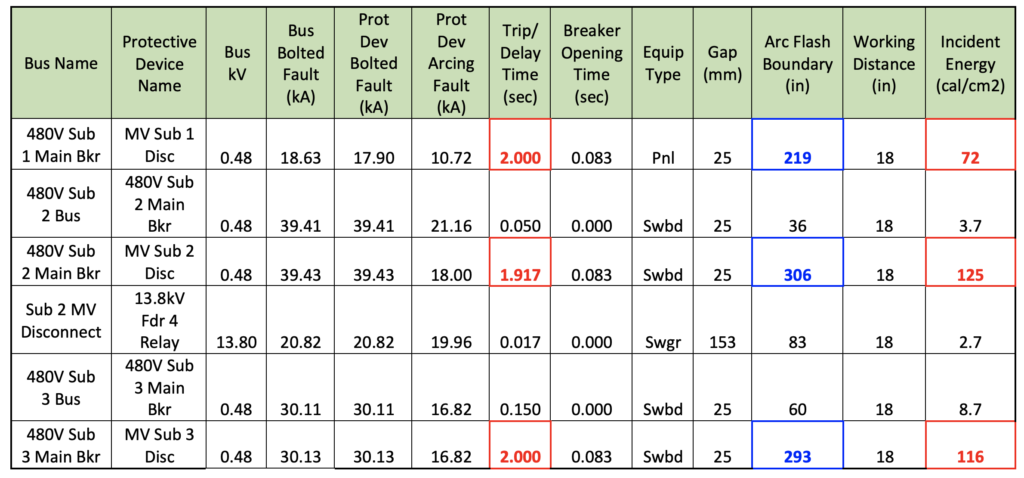

The next most significant section to skip to is the Arc Flash Results table, typically several tabs into the assessment. You will find several pages of tabled results that look something like this:

What to look for in the arc flash assessment results table:

-

Bus Names with the highest Incident Energy rating below 40 cal/cm2

- Workers can safely expose themselves to these buses while energized, provided they possess properly-rated Personal Protective Equipment (PPE) equal to or greater than the Incident Energy rating of that equipment.

- The maintenance department should maintain awareness of these ratings and ensure proper personal protective equipment (PPE) when exposed to energized parts within this equipment. If not, inform plant leadership, as they bear ultimate responsibility for supplying workers with properly-rated personal protective equipment (PPE) for all live work (in accordance with OSHA 29 CFR 1910).

-

Bus Names where the Incident Energy is greater than 40 cal/cm2

- This means this particular piece of equipment is classified as “Dangerous” when equipment is open while energized, and no amount of Personal Protective Equipment (PPE) will sufficiently protect workers within the Arc Flash Boundary, should an arc fault occur.

- Take necessary steps to avoid performing work on this equipment while it is live, or implement engineering controls to decrease incident energy levels and/or exposure to live conditions.

-

The Lower the Trip/Delay time, the lower the Incident Energy

- The Trip/Delay time is the amount of time it takes the current protection to extinguish or clear an arcing fault. Upstream fuses or protective relays trip an upstream disconnecting device to typically accomplish this.

- The high Incident Energy values (in red) correspond to the higher Trip/Delay times, with 2.0 seconds typically being the maximum amount of clearing time most modeling software allows for energy calculations.

- The current protection is inadequate for extinguishing the available arcing fault current when trip times are close to or equal to 2 seconds. Therefore, it is essential to review and adjust the protection accordingly.

-

Arc Flash Boundaries are critical to keeping unprotected personnel safe

- Arc flash Boundaries are calculated to ensure that no Incident Energy greater than 1.2 cal/cm2 will be felt outside that distance from the exposed energized equipment. 1.2 cal/cm2 is equivalent to a second-degree burn, so you certainly want to be outside that defined boundary.

- The higher the Incident Energy levels, the longer the Arc Flash Boundaries must be (in blue). Energized parts within the equipment apply these boundaries only when they are exposed (for example, when doors are open or cover panels are off). Unprotected personnel must receive awareness about the locations of these boundaries through signs, barricades, and other related measures.

- It’s crucial to pinpoint the exact locations of equipment with higher Arc Flash Boundaries. This information helps assess potential impacts on personnel or production when live work is necessary on that equipment. Proper planning could limit or avoid these impacts.

-

The best way to manage high Incident Energy levels is to reduce them through engineering controls

- There are often several available methods to reduce the overall Incident Energy levels of your facility’s equipment. They can range from very simple (adjusting protective settings on a relay) to more complex (upgrading your protective scheme).

- It’s usually best to reach out to an electrical service contractor (like Southwest Electric Co) and ask for recommendations on how to reduce Incident Energy levels for your higher-risk equipment. This will not only provide greater safety to your employees but will also reduce risk to equipment and productivity.