By Mike Switzer, Product Line Manager

Though DC Motors are simple machines, proper and timely maintenance is important to lengthen the motor and facility’s lifespan. DC motor users in the manufacturing sector know all too well the headaches that can come along with troubleshooting issues. This article will help you troubleshoot six of the most common DC motor issues.

1. Carbon Brushes

With DC motors, you must apply them with the proper amount of load. This is very important for brush conductivity on the commutator and the current density so the brushes can maintain a certain lubricity when contacting the commutator under load. When an applied load is not consistent and the motor has the wrong grade of brushes, the carbon brushes can wear out prematurely, causing carbon dust to accumulate within the motor. This issue can wear the commutator bars to a point of irreversible damage. A carbon brush survey could be of value to investigate the proper grade of brush for each of your applications.

It is also important to keep proper, constant pressure on the brush to the commutator to deliver the full current density at the point of contact in order to alleviate premature wear on the brushes. Carbon dust is destructive to the insulation. You must maintain by way of removing the dust within the motor to prevent low megohmmeter readings. A good way to prevent carbon build up is to use compressed air to help remove any lingering dust from within the motor. A very low megohmmeter reading can notify the DC drive to shut down the power to warn of a potential to ground.

2. Brush Rack Adjustment

To achieve the ‘neutral’ position, you must properly adjust the rack or yoke component. To achieve this, properly position the adjacent brushes on the commutator. Ensure they are in an area outside or between the polarity reference of the armature coils that receive voltage across the brushes. Keeping the brushes in a neutral position can prevent excessive arcing while under load. Changing loads can be difficult to get right. Setting the neutral can be adjusted and performed onsite when applicable.

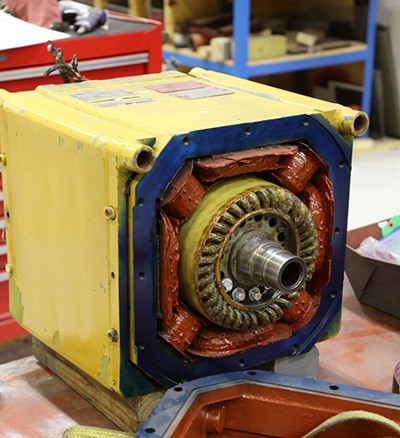

3. Commutator Maintenance

Like carbon brushes, the commutator requires maintenance from time to time. The bars on a commutator must be maintained by way of machining the segmented commutator bars true. The segments are insulated between bars with a molding mica. Some larger DC motors may be able to be machined onsite to prevent unnecessary extraction of the motor. It is very important to keep proper maintenance schedules to ensure the commutator stays round without run-out on the surface. If the eccentricity of the commutator is not acceptable, you could end up with broken brushes and/or brush springs. A commutator that is out of round can also lead to potential high bars, which can damage the brushes and cause excessive arcing where the brush contacts the copper bars. A well-balanced armature is also recommended to prevent the brushes from causing any unnecessary damage to the commutator.

Keep in mind that carbon dust will accumulate between the bars of the commutator and can produce a potential for a bar-bar short. When a commutator is machined, it’s typically a good idea to undercut the mica insulation in-between each bar while chamfering the top edges of the sides. This will give a smoother surface for the carbon brushes to make contact.

Keeping the commutator eccentricity at a bare minimum will provide you longer lasting runtime. Remember that downtime equals money lost.

4. Winding Issues

Other common DC motor issues could be a failed field winding or interpole winding. Either winding can show up as arcing at the brushes. The correct data for replacing a failed winding is engineered to the manufacturer’s exact specifications. When you do not have an on-staff engineer, the Electrical Apparatus Service Association group has plenty of information to get your motor back with the proper data like it’s new. When a DC motor is left idle and the drive isn’t set up with a field weakening option, you will have trouble with heat from the field windings. Most medium to large DC motors will have some type of blower system attached to alleviate this problem.

5. Mechanical DC Motor Issues

As with any electric motor, proper mechanical maintenance is imperative. You must properly lubricate and maintain the bearings if longevity is the goal. Motor assembly will also need to be done in the

correct way to alleviate bearing issues, such as misalignment within the end frame housings (misaligned bearing retainers/stator to end frame mounting). Proper installation and alignment are

factors to take into consideration so that the motor can keep running at its peak performance.

6. Drive Maintenance

DC drives can also be a culprit to a non-efficient DC motor. Detect excessive arcing at the brushes to the nearest ground/metal surface within the end frame on the commutator side of the motor to identify issues with the silicon-controlled rectifiers (SCRs) in a drive. DC drives today program the specifications for horsepower, volts, and amperes under load. The drive may also have the option to mount a tachometer on the end of the motor shaft. If the tachometer or connections to the drive are not properly terminated, the motor can go into an overspeed mode by the means of over-voltage at the armature. The drive reacts to little or no voltage produced by the tachometer. DC drives are designed to shut down the motor in cases such as this.

A DC motor is a motor all unto itself. Simple yet complicated. Proper maintenance of the brushes, brush springs, and commutator will always be a need. There is no better feeling than when you install a motor and it starts making money for your business.

Southwest Electric has the expertise to help maintain and keep your motor running at its peak capability. We can create and implement a custom maintenance program that will maximize the life of your DC applications. Give us a call, email, or request a quote using the button below to get in touch with us today.

Have a question about AC Motor issues? Read our AC Motor article!

Want to Learn More: Check Out Our YouTube Video!

Click below for our other Motor videos!

What is the Difference Between a Form Coil and a Mush? (youtube.com)