Southwest Electric Company’s Specialty Transformer Division specializes in the design and manufacturing of liquid-filled transformers (both standard and custom-designed), from 25 kVA up to 7500 kVA.

View our current inventory to find the product you need shipped immediately.

Long-Time Industry Leaders

Our skilled team of electrical and mechanical engineers has decades of experience designing pad-mounted transformers for a wide range of applications, including:

- Oil and gas down-hole equipment (including submerged pumps with variable speed drives)

- Surface pumps

- Small utilities requiring distribution-style transformers

- Industrial clients

We design and test each unit in-house to meet all industry standards, including IEEE, ANSI, NEMA, UL, and C-UL.

Fast Response Time

At SWE, we know how important it is for you to minimize any potential downtime, so we respond quickly to all your needs:

- Average RFQ response time: 48 hours

- Average lead time for standard transformers: 3-5 business days (varies with supply availability)

- Finished goods inventory, standard stock, and JIT manufacturing will often minimize lead times.

- Average delivery time for custom transformers: Varies based on product complexity

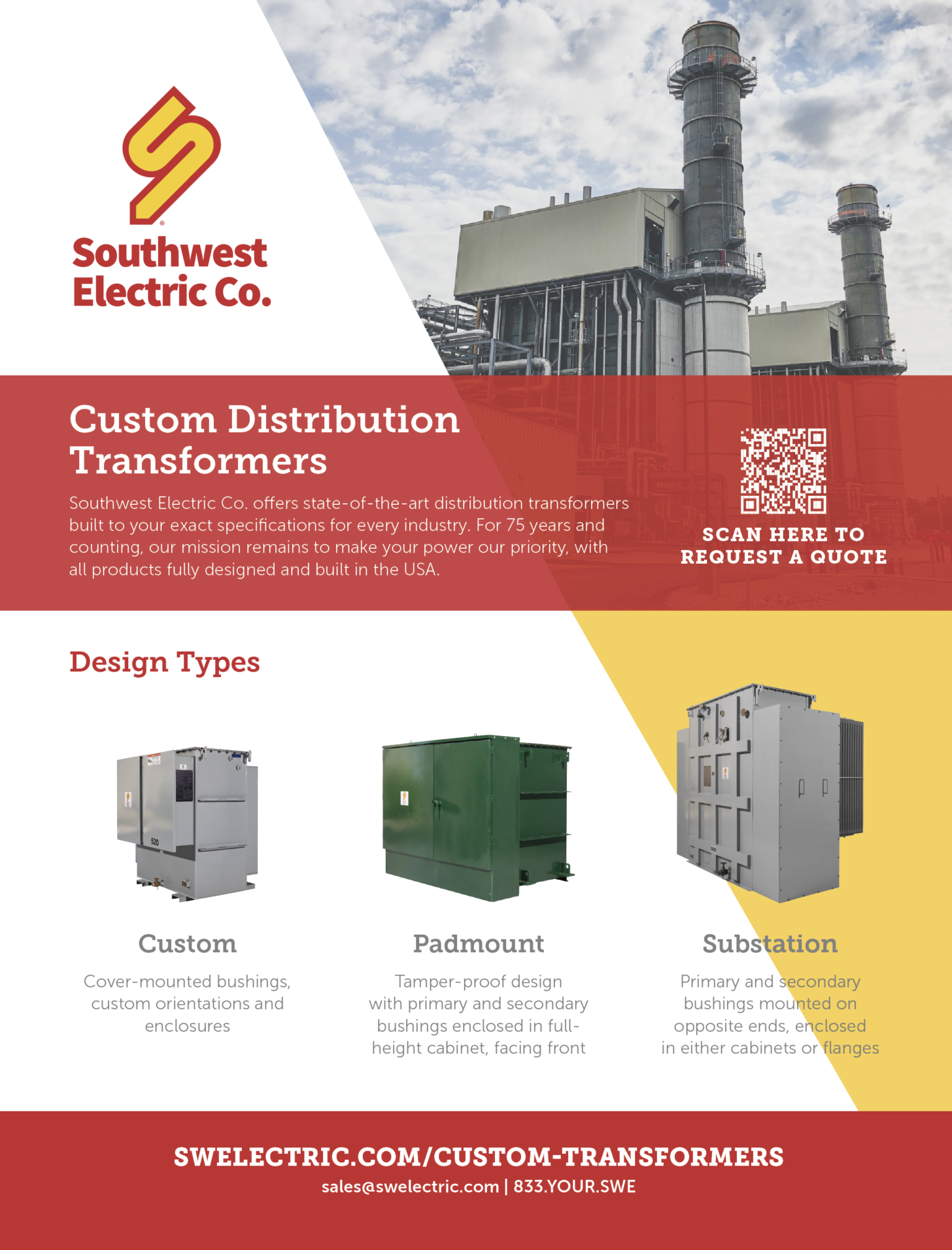

Specialty Transformer Types

Some applications call for a standard transformer, while others require a custom solution. Our transformer team can work with you to identify the exact specifications you need, and we have the expertise and experience to customize your transformer when necessary. Available custom features include:

- 25 kVa – 2500 kVa single-phase transformers

- 75 kVa – to 8400 kVa three-phase transformers

- 120 Volt to 34500 Volt class

- Designs for non-standard frequencies and high harmonic conditions

- Transient suppression

- Mineral oil or high-fire-point insulating fluid

- Designs for extreme conditions:

- Extreme ambient temperatures

- Hazardous locations

- High altitudes

- Paint systems for extreme environments

Soft Starter Reactor

Designed for starting large motors, this device detects and responds to voltage drops. The soft starter incorporates a vacuum contactor and timing circuits for auto bypass of the reactor after the motor achieves full speed, and features a tap switch to match the reactance to the application.

Multi-Tap Transformers (FACT® Series)

Our FACT® (full amp capacity transformers) series is a broad line of single-phase and three-phase distribution-style transformers. They are primarily designed for the rigorous duties of down-hole submersible pumps, surface pumps, and variable speed drive applications.

Single-Phase Transformers: Single-phase step-down FACT® transformers are available with single primary voltages (FACT® 125) or dual primary voltages (FACT® 225).

Three-Phase Transformers: Our FACT® III series are three-phase step-up designs with a 480 V primary voltage.

Phase-Shifting Transformers

Our phase-shifting transformers convert three-phase utility voltage to provide the 12, 18 or 24 (or higher) pulses required to feed modern multi-pulse variable frequency drives (VFDs). By using a multi-pulse VFD, you can reduce the need for expensive harmonic filters. Our phase-shifting transformers come in a variety of models to match the size of the VFD and the FACT® multi-tap transformer connected to its output.

Poly-Auto Transformer: A 12-pulse phase-shifting transformer, this polygon auto transformer is designed to supply a 12-pulse motor drive, and reduces the need for expensive harmonic filters.

18- and 24-pulse models: We also offer 18-pulse and 24-pulse phase-shifting transformers (and higher) as custom designs. Contact us for more information.

Transformer Repair & Maintenance

In addition to designing and manufacturing new transformers, we also offer transformer repair, service, and testing – both in our shop and on location. Read more about our transformer field services.

Building a Long-Term Partnership

With a decades-long track record of innovation, quality, and service, SWE can be a trusted partner for all your transformer needs. Get a quote or learn more about our transformers.